Saddleworth Secondary School newbuild under the Government’s Priority School Building Programme

Chemical Resistant Classes at New School

A former pallet works in Saddleworth is the home for a new secondary school (11 – 16 years). Saddleworth School is being rebuilt under the Government’s Priority School Building Programme (PSBP). The new location for the school is the mining town of Diggle, 2km away from the current school. Interestingly, the new 22-acre site has had several industrial uses and records dating back to 1854 show that the site was initially used as a mill; demolished in the early 1900’s, the mill made way for a loom works. More buildings were constructed until the land was taken over by W.H. Shaw Pallet Works, reputedly one the largest factories of its type in Europe. The factory assisted in the war effort during WW1 when the buildings were used for munitions, and in WW11the factory made parts for Russian submarines.

To make way for the new larger capacity school all the industrial buildings have been cleared, except for a gothic clock tower that forms part of an original administrative building that is grade II listed.

The site investigation report assessed the ground gas regime as a Characteristic Situation 2, requiring gas protection measures to mitigate the risk, however, more in-depth modelling using specialist software, unique to ITP, found levels of hydrocarbon contamination.

Special consideration should be given to sites contaminated by hydrocarbons or VOCs as the mobile compounds migrate with relative ease through unsuitable membrane materials. Aluminium laminates are superb gas barriers, but these materials will delaminate when exposed to hydrocarbon vapour/VOCs and the aluminium layer is susceptible to oxidation due to moisture penetrating exposed edges.

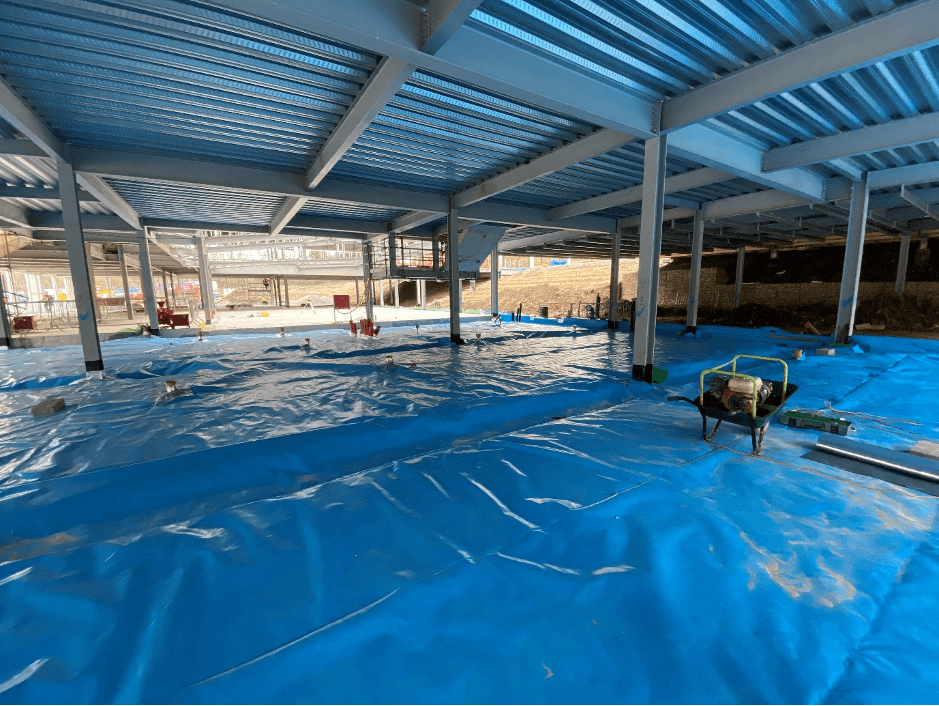

Speaking about the project Bryan Woodcock, Company Director of SPS Substructure Protection, the installers at the site explained “We specifically needed a VOC barrier solution that offered complete protection against a wide range of ground borne contaminates, but one that would not require additional products, would be easy to install, and at a competitive price.

ITP’s Powerbase© VOC ticked all the boxes, and I was assured of solid service and support from the company, which over the years, has become on par with having a specialist extension to my team”. Powerbase© VOC, is a specially engineered multilayer composite barrier membrane,

Powerbase© VOC is made from protective polymeric layers on both side of a chemical resistant hydrocarbon barrier inner core, offering exceptional resistance to hydrocarbons and VOCs (volatile organic compounds), it complies with Ciria C748, BS8485, NHBC Chapter 4.1 and NHBC Red Gas Protection Measures.